As a general rule, patrols transported their explosives unarmed. That is: fuses and detonators were carried separately from the explosive devices to prevent accidental detonation. Even the Mills bombs, with the exception of a few needed for emergencies, were often carried with the fuses removed. When crossing the harsh desert terrain patrols often faced more dangers from shifting primed explosives than ambush.

Grenades

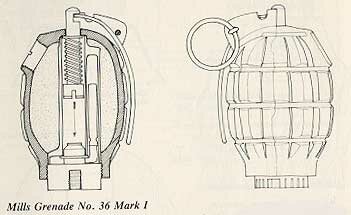

N0. 36 Mills Grenade

Developed by William Mills of Birmingham in 1915, the standard issue grenade in the British Army, from the end of WWI until 1972 was the No. 36 Mills Grenade (Mills bomb). The No 36 is arguably the most recognized grenade the world over.

It was carried by all patrols. Initially the Grenade had a delay fuse of 7 seconds to allow its use as a rifle grenade. Troopers were suppose to cook off the grenade (pull the pin and release the safety lever and hold the grenade for three seconds) before throwing it as a hand grenade. This was not only impractical but just as dangerous as throwing a grenade with a 7 second delay. The problem with the long delay, is it gave the enemy an opportunity to pick up the grenade and throw it back!

The delay fuse was cut to 4 seconds. (However, 7 second Mills Bombs were still issued for use as a rifle grenade.)

Characteristics

Type: Defensive, Fragmentary

Weight: 1 pound 11 ounces

Delay fuse: 4 or 7 seconds

Bursting Radius: 80 yards

(This is the quoted burst radius but I highly doubt this is the actual Effective radius as it is well within the throwing distance. It is probably the maximum burst diameter A more probable effective bursting radius is about 15-20 yards)

N0. 36 Mills Grenade for EY Rifle

When fired from the EY Rifle, the Mills bomb was modified by unscrewing its base plate and replacing it with a 2 1/2 inch diameter gas plate. The gas plate was a simple metal disk that fit snuggly in the base of the EY cup and prevented gas from slipping around the edges of the grenade. mills bombs also had the 4 second fuse replaced with a seven second fuse.

Before the EY rifle was invented, the Mills bomb had a long pin screwed into the bottom that was inserted down the barrel. This was less reliable as this rod could get hung up in the barrel and the seven second fuse was crucial as once the pin was pulled the safety spoon would flip off. This gave the grenadier a few seconds to aim the launcher and still provide adequate loft time for the grenade once fired.

With the cup, the grenade can be inserted into the the cup while the safety spoon is still in place, thus the 7 second delay is not as necessary and the grenade will not explode unless it falls out the cup. Rifle launched grenades were mentioned as useful in both Barce Raid and attack on the fort at El Ezzeiat.

N0. 69 Grenade (offensive grenade)

The British No. 69 was an offensive grenade (commonly called a flash or concussion grenade today) It was developed in 1940 and used throughout the war. Unlike the Mills bomb it was not fragmentary. The body was made of bakelite, a hard plastic. A metal sleeve could be fitted over the no. 69 to create a fragmentary grenade.

The No. 69 was activated by unscrewing the cap protecting the allways fuze. The cap was actually the grenades safety Once thrown the allways fuze would arm the grenade. The grenade would explode on impact. (see below for description of allways fuze)

- Weight : 13.5 oz. (383 grams)

- Length 4.5 inches (with cap)

- Diameter 2.5 inches

- Filling High explosive

- Fuze: Allways (Impact)

Allways Fuze

An "Allways fuze" is an impact-only fuse. Basically it is weighted strip of cloth tape that would unravel when the grenade was thrown. Once unraveled the lead weight would pulled a safety pin which freed a bearing and armed the detonator. The grenade would then explode upon impact with any object or the ground. The term "Allways" refers to the fact that no matter how the grenade impacts, it will still explode.

The Allways Fuze

Top: Tape un-spooled with lead weight at end.

Bottom: As it would appear screwed in top of grenade, with the cap removed.

N0. 68 Grenade (anti-tank grenade)

The No. 68 anti-tank grenade was developed to be used with the EY grenade launcher. It was one of the earliest shaped charge grenades, being developed in 1940. It may have actually been the first High Explosive, Anti Tank (HEAT) device in use. The design was quite simple. The war head was stabilized by some crude fins. Upon preparing for fire, a safety pin was removed from the tail. Once fired the fuse would be primed and on impact (despite the angle of impact), the grenade would explode. Detonation occurred when the striker in the tail of the grenade was thrown forward into the fuse. If the grenade impacted horizontally (at 90 degrees) against the armor it was capable of penetrating about 2 inches of armor. The grenade was somewhat effective against personnel with a limited burst radius and the casing of the projectile acting as shrapnel.

The grenade was quite large and extended beyond the cup on the EY rifle. However the gas plate on the end of the fins and the fins kept the grenade seated in the cup until fired.

- Weight: 894 grams

- Filling: Lyddite, Pentolite or RDX/Beeswax

- Filling weight: 156 grams

- Fuze: Impact

Sabotage

Lewes Bomb

flammable liquid (motor oil). Using a delayed fuse, the charge was placed on enemy aircraft. The preferred location of placement was where the wing met the fuselage . This was thought to be the best place to cause the most damage. (Aircraft often had their fuel cells in the wings.)

The Lewes bomb came about because grenades and other explosive devices proved unreliable. Lewes' formula was a pound of plastic explosive, a quarter pound of thermite mixed with a bit of engine oil. Inside the mass was inserted a 2-ounce dry guncotton primer and detonator and a thirty-second fuse. The most common ignition method used was time pencils or pencil detonators. Others included release switches and pressure switches.

The Lewes bomb was a field expedient explosive. It is unclear what the container for the explosive was but it was probably a simple canvas sack or pouch coated with a sticky substance to ensure adherence to the surfaces. The bomb was usually placed and not thrown.

Plastic Explosive (Nobel 808)

Plastic Explosive is a type of explosive material that is stable over a wide temperature range, easily shaped by hand, and relatively stable, most types can be struck and /or burned with causing an explosion. The most common plastic explosive used by the British during World War II was developed by the Nobel Chemicals Ltd. and was commonly known as "Nobel 808". It looked like green Play-d oh and smelled faintly of almonds. During WW2 it was extensively used by the British Commandos, Royal Engineers and the Special Operations Executive (SOE) .

Timing Pencils

Timing Pencils were a cheap and effective fuze/detonator combination. One of the most commonly used was the N. 10 delay switch , or officially, "Switch, No. 10, Delay". The second most common was probably Switch, No. 9, L Delay; the "L".

The No. 10, delay, is made or a brass (and later aluminum) tube with a copper section at one end which contained a glass vial of a cupric chloride. Below the vial was a spring loaded striker held under tension. A thin metal wire kept the striker in place. To start the timer, the copper portion of the tube was crushed by striking, bending or otherwise denting it which in turn broke the vial of cupric chloride and the safety pen is removed. The cupric chloride would then eat away at the thin wire which would release the striker. The striker would then shoot down the brass tube, and hit the percussion cap which would ignite the detonator. This is turn would ignite the Nobel 808 or other explosive material. The length of delay was dependent on the concentration of cupric chloride; the more concentrated, the shorter the delay. Timing Pencils had delays from 10 minutes to 24 hours; however they were not accurate to the second. For instance a pencil with an hour delay may go off 2 or 3 minutes before or after that hour. At 12 hours, the delay may be as little as 11 hours or as much as 13 hours. Temperature and humidity would affect the length of delay.

The No. 11 was mechanical in nature consisting of a spring with a small notch cut into it. With the spring was put under tension it would begin to stretch. Eventually the spring would fail where it had been notched and the striker would be released. The No 11 was not as reliable as the No. 10 but because the No. 10 was not always water tight the No. 11 was normally first choice for underwater demolition. (Water could seep into the No. 10 pencil and dilute the cupric chloride possibly causing the detonator to fail.)

The pencils were normally issued five to a pack, with all five in the pack being the same length of time. Typically when using the pencils, two detonators would be placed in the explosive charge. The detonators would normally come from two different stocks, if possible. This was done in case one detonator failed.

Switch, No. 10, Delay

Land Mines

GS Mark. V Anti-Tank Mine

The he Mk. V mine was designed to disable tanks or other vehicles. The mines came packed in a wooden box, five to a box with 20 fuses stored separately. AT mines typically required more pressure to set off, thus allowing an individual soldier or small animal to step on them harmlessly but when a heavier object applied pressure it would go off.

Characteristics:

- Weight: 8 pounds

- Diameter 8 inches

- height:4 inches

- Explosive: 4.5 pounds of TNT or Baratol

- Case: Steel

- Color Khaki-green

Read more: